Contactor vs. Motor Starter: Core Differences

Electric motors are a common and essential part of many industrial systems.

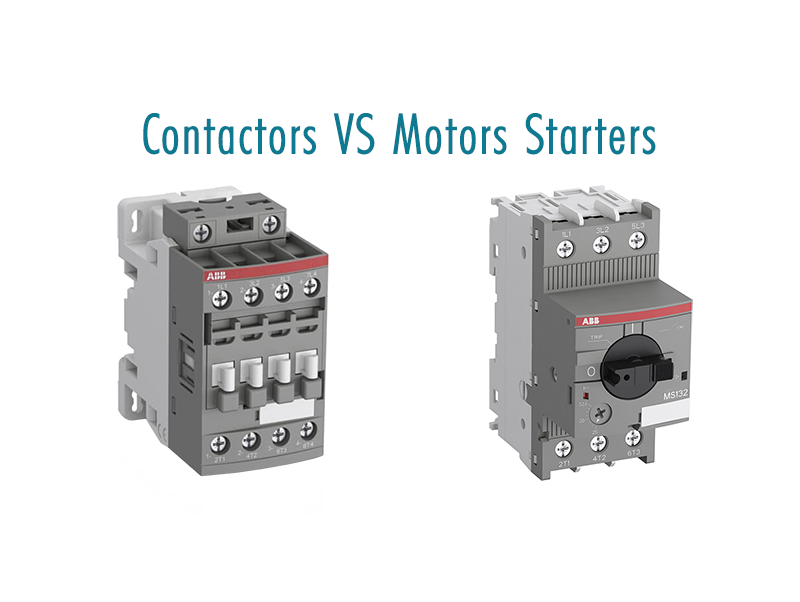

But to operate them safely and efficiently, they require either contactors or motor starters. Both contactors and motor starters serve the same purpose: to control the starting, stopping, speed, torque, direction of rotation, and other operational parameters of an electric motor.

However, there are some critical differences between contactors and motor starters that you should understand before selecting the right device for your application.

This article will discuss the core differences between a contactor and a motor starter so you can make an informed decision when choosing which one is best suited for your needs.

First, what is a Contactor?

A contactor is an electrical relay that switches circuits on or off.

It consists of two contact sets: the main and auxiliary. The main contact set controls the current flow through the main circuit, while the auxiliary contact set controls other operations, such as a pilot light or alarm system. They are both designed to handle heavy loads in motors, lighting systems, heating, HVAC, and more.

Contactors are rated based on their maximum voltage capacity, contact gap distance, and contact surface area. They are typically used in electric motors, heating systems, and lighting circuits.

How does a Contactor work?

A contactor uses an electromagnet to open and close its contact sets.

When energized, the contactor's coil attracts an armature that opens or closes the contact sets depending on the direction of the current flow. This allows a contactor to control the power supply to electrical circuits safely and reliably.

Next, what is a Motor Starter?

A motor starter is an electrical device used to control an electric motor's operation.

It consists of contactors, overload relays, and other components designed to regulate the flow of power to the motor to protect it from damage. It also protects against thermal overloads and short circuits.

Motor starters are rated by their current capacity, contact gap distance, and the maximum motor horsepower they support. They are typically used in applications such as air compressors, pumps, fans, and conveyor systems.

How does a Motor Starter work?

A motor starter works by monitoring the current flow to the motor and cutting off power when certain conditions are met.

This prevents damage to the electric motor due to thermal overloads, short circuits, or other electrical faults. The contactor portion of a motor starter is designed to switch on and off quickly and reliably, while the overload relays provide additional protection against faults.

Key differences between Contactors and Motor Starters:

|

Contactor |

Motor Starter |

|

Electrically controlled switch (similar to a relay.) |

Electrically controlled switch with an overload relay. |

|

Applies voltage to the coil, which closes contacts and supplies or interrupts power to a circuit. |

Uses overload relays to protect against load surges and overheating on the motor. |

|

Classified by voltage capacity. |

Classified by current capacity and motor horsepower. |

|

Has normally open (NO) contacts. |

Has normally open (NO) or normally closed (NC) contacts, depending on function. |

At a high level, the primary difference between contactors and motor starters is the type of protection they provide.

Contactors are designed to switch on and off, whereas motor starters have additional components that protect against thermal overloads, short circuits, and other potential faults.

Additionally, there’s a big size difference between the two, making each right for different applications. Contactors are much smaller than motor starters, so they are better suited for applications where space is limited. Ultimately, contactors and motor starters both serve the same purpose of controlling electric motors but offer different levels of protection in the process.

So, which one should you choose: a Contactor or Motor Starter?

The choice between contactors and motor starters depends on the specific application.

Contactors are the way to go if you need a basic, cost-effective solution for controlling an electric motor. However, if you want to ensure maximum protection for your motor, then a motor starter is the better option.

It's essential to make sure you select the right device for your application to ensure optimal performance and safety. With that said, contactors and motor starters are both crucial pieces of equipment that play a critical role in many industrial systems.